Industrial Lighting Energy Best Practices

Finding the right lighting for any location may seem like a careful balancing act. It needs to be efficient in terms of energy used while still providing ample illumination. When considering the right lighting for an industrial setting, these factors are always at the forefront of the decision. Here are a few industrial lighting energy best practices to help you get the most efficient lighting solution possible.

- Play up any natural lighting in the location. If you have windows or bay openings in the location, utilizing natural light will help reduce the amount of energy consumed using artificial lights.

- Consider the use of occupancy sensors. Regardless of what type of lighting you choose, an occupancy sensor or other timing device can greatly reduce the amount of energy being consumed. They can easily be installed to almost any new or existing fixture and can save your business a good deal of money.

- Invest in reflectors. This is often one of the more easily forgotten industrial lighting energy best practices. Installing reflectors in your fixtures will help to distribute the light more evenly instead of simply casting it downwards and limiting the scope of the lumen output.

- Choose the right lighting type. It is an obvious fact of lighting that certain types of lighting are more energy efficient. The least energy efficient tends to be halogen and incandescent. They have lower lumen outputs and higher watts which means the energy consumed is higher than other options. Fluorescents are a better choice since they have better watt to lumen output ratios, but they aren’t as long-lasting as induction lighting or LED. These are the two best options for industrial settings.

- Compare LED and induction. Induction lighting is often seen as comparable to LED in terms of performance and longevity, but there are a few differences to keep in mind. Induction lighting will give an average of up to 90 lumens/watts which is better than fluorescents or any of the other non-LED options. However, LED tends to give up to 120 or higher lumens/watts which is still the more energy efficient option. Both types are pretty much the same regarding average rated life with both averaging around 100,000 hours of use. However, induction lighting contains mercury which is harder to dispose of and potentially harmful to the environment whereas LED is free of this component.

Choosing energy efficient lighting is the best way to help lower energy costs while maximizing lighting potential. Following these basic tips will make finding the right solution easy and simple.

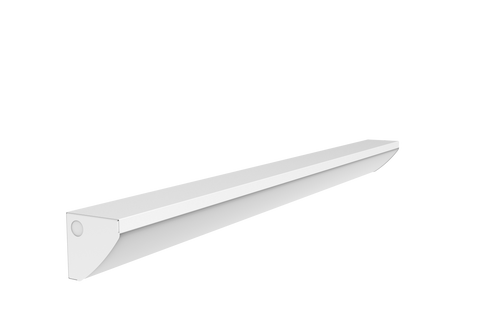

4 Foot LED Stairwell / Corridor Light, 4600 Lumen Max, Wattage and CCT Selectable, 120-277V

4FT LED Narrow Strip Light, 5500 Lumen Max, Wattage and CCT Selectable, 120-277V

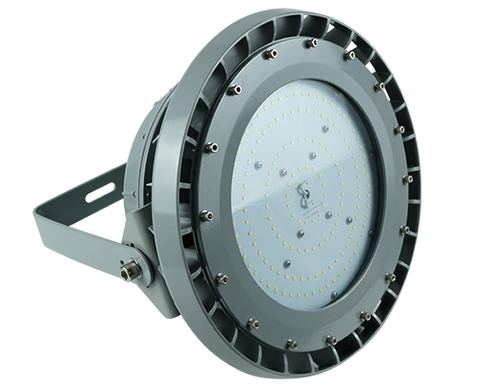

LED Explosion Proof Hazardous Location Light, Class 1 Division 1, 11200 Lumens, 80W, 5000K, 100-277V, C Series

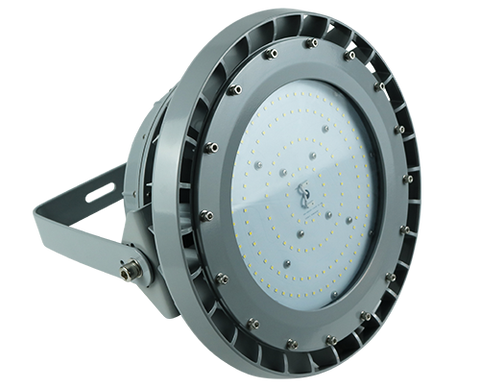

LED Explosion Proof Hazardous Location Light, Class 1 Division 1, 21000 Lumens, 150W, 5000K, 200-480V

For the best selection of industrial strip lights online, look no further than Warehouse-Lighting.com. From staggered to shop light strips, our products provide powerful lighting solutions for your unique needs. Shop for commercial-grade strip light fixtures today!

View (77) Products

Find explosion proof LED lighting for the harshest environments at Warehouse-Lighting.com. We have a large selection of explosion-proof lights available in a variety of ratings and classes that will withstand the hazardous areas and applications that require explosion proof lights. Purchase the best explosion proof LED light fixtures with the experts at Warehouse Lighting.

View (83) Products

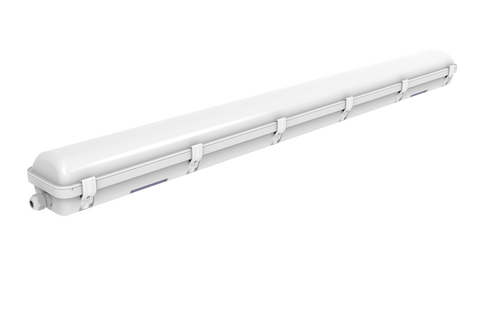

Vapor proof light fixtures are the top illumination choice for harsh environments. Available in multiple types, vapor tight led light fixtures provide ample illumination for indoor or outdoor applications. Shop vapor tight lights online at Warehouse-Lighting.com for the light to handle any job!

View (110) Products High Bay LED Lighting

High Bay LED Lighting

Industrial Low Bay Lighting

Industrial Low Bay Lighting

Industrial Strip Lights

Industrial Strip Lights

Vapor Tight Lighting

Vapor Tight Lighting

LED Shop Lights

LED Shop Lights

Hazardous Area / Explosion Proof Lighting

Hazardous Area / Explosion Proof Lighting

Loading Dock Lights

Loading Dock Lights

Construction / Portable Lighting

Construction / Portable Lighting

High Temperature LED Lights

High Temperature LED Lights

Industrial Ceiling Fans

Industrial Ceiling Fans

LED Work Lights

LED Work Lights

Networked Controlled Lighting

Networked Controlled Lighting

NEW Warehouse Lighting Fixtures

NEW Warehouse Lighting Fixtures

American Made Industrial Lighting

American Made Industrial Lighting

Clearance

Clearance

Troffer Lights

Troffer Lights

LED Flat Panel Lights

LED Flat Panel Lights

Drop Ceiling Lights

Drop Ceiling Lights

Suspended LED Lights

Suspended LED Lights

LED Cylinder Lights

LED Cylinder Lights

Exit / Emergency

Exit / Emergency

Wrap Lighting Fixtures

Wrap Lighting Fixtures

Gooseneck and Barn Lights

Gooseneck and Barn Lights

Stairway & Corridor Lighting

Stairway & Corridor Lighting

Hospital Bed Lights

Hospital Bed Lights

Recessed Lighting

Recessed Lighting

Wafer Lighting

Wafer Lighting

RGB LED Lights

RGB LED Lights

Grow Lights

Grow Lights

Refrigeration Lighting

Refrigeration Lighting

Commercial Sign Lights

Commercial Sign Lights

LED Track Lighting Fixtures & Systems

LED Track Lighting Fixtures & Systems

UV Disinfecting Lights & Air Purifier Fixtures

UV Disinfecting Lights & Air Purifier Fixtures

American Made Commercial Lighting

American Made Commercial Lighting

LED Flood Lights

LED Flood Lights

Outdoor Wall Lights

Outdoor Wall Lights

LED Area Lights

LED Area Lights

Parking Lot Lights & Poles

Parking Lot Lights & Poles

Outdoor Post Top Lights

Outdoor Post Top Lights

LED Stadium Lighting

LED Stadium Lighting

Canopy Lights

Canopy Lights

Security & Motion Sensor Lights

Security & Motion Sensor Lights

LED Bollard Lights

LED Bollard Lights

Outdoor LED Linear Light Fixtures

Outdoor LED Linear Light Fixtures

Solar Powered LED Lighting

Solar Powered LED Lighting

Dusk to Dawn Lights

Dusk to Dawn Lights

Landscape Lighting

Landscape Lighting

Outdoor String Lights

Outdoor String Lights

Coastal Wildlife Lighting

Coastal Wildlife Lighting

Outdoor House Lights

Outdoor House Lights

American Made Outdoor Lighting

American Made Outdoor Lighting

Architectural Linear Lights

Architectural Linear Lights

Architectural Grid Mount Lights

Architectural Grid Mount Lights

Architectural Round Pendant Lights

Architectural Round Pendant Lights

Architectural Square Linear Lights

Architectural Square Linear Lights

Architectural X-Shaped Linear Lights

Architectural X-Shaped Linear Lights

Architectural LED Wall Packs

Architectural LED Wall Packs

Ceiling Fans

Ceiling Fans

Ceiling Lights

Ceiling Lights

Chandelier Lights

Chandelier Lights

Pendant Lighting

Pendant Lighting

Island Lights

Island Lights

Under Cabinet Lighting

Under Cabinet Lighting

Vanity Lights

Vanity Lights

Wall Sconces

Wall Sconces

LED Tape Lights

LED Tape Lights

LED Mirrors

LED Mirrors

LED Light Bulbs

LED Light Bulbs

LED Tube Lights

LED Tube Lights

LED Corn Lights

LED Corn Lights

Vintage LED Bulbs

Vintage LED Bulbs

Decorative LED Bulbs

Decorative LED Bulbs

Fluorescent Light Bulbs

Fluorescent Light Bulbs

Metal Halide Lamps

Metal Halide Lamps

LED Magnetic Strip Retrofit Kits

LED Magnetic Strip Retrofit Kits

LED Strip Light Retrofit Kits

LED Strip Light Retrofit Kits

High Bay LED Retrofit Kits

High Bay LED Retrofit Kits

LED Troffer Retrofit Kits

LED Troffer Retrofit Kits

LED Wall Pack Retrofit

LED Wall Pack Retrofit

LED Street Light Retrofit Kits

LED Street Light Retrofit Kits

Recessed Lighting LED Retrofit Kits

Recessed Lighting LED Retrofit Kits

Ballasts & Drivers

Ballasts & Drivers

Emergency Ballast For LED & Fluorescent Lights

Emergency Ballast For LED & Fluorescent Lights

Electrical Supplies & Mounting Kits

Electrical Supplies & Mounting Kits

Electrical Tools

Electrical Tools

Switches & Receptacles

Switches & Receptacles

Electrical Power Cords

Electrical Power Cords

Sensors and Timers

Sensors and Timers

Smart Home Automation

Smart Home Automation

High Bay Occupancy Sensors

High Bay Occupancy Sensors

Electric Vehicle Chargers

Electric Vehicle Chargers

Hand Dryers

Hand Dryers

LED Shop Lights

LED Shop Lights

Garage LED Light Fixtures

Garage LED Light Fixtures

Office Lights

Office Lights

Classroom Lights

Classroom Lights

Church Lights

Church Lights

Gym Lighting

Gym Lighting

Factory Lights

Factory Lights

Hospital Lights

Hospital Lights

Walkway Lights

Walkway Lights

Parking Lot Lights

Parking Lot Lights

Exterior Building Lights

Exterior Building Lights

Sports Lighting

Sports Lighting

Airport Lights

Airport Lights

NSF Rated Lights

NSF Rated Lights

TAA LED Lighting

TAA LED Lighting

Restaurant Lights

Restaurant Lights

Corridor Lights

Corridor Lights

Barn Lighting

Barn Lighting