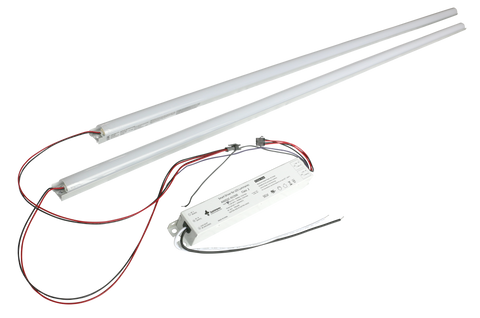

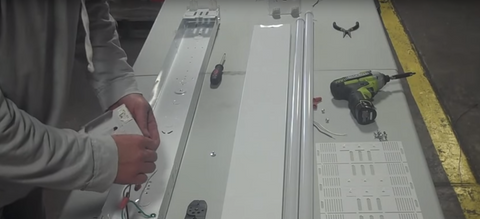

When it comes to saving energy and money with your lighting solutions, LED technology is the way to go. If you already have fixtures in place that you are looking to convert for energy-savings, it is an easy option to retrofit a fluorescent strip fixture to LED. It doesn’t make sense to buy a whole new fixture for the power of LED when we have kits that can make this a relatively quick and easy solution. Here are a few things to know about how to retrofit a fluorescent strip fixture to LED.

- Never work on a fixture with power running through it. Double check to ensure there is no power. Also, make sure you use wire nuts or electrical tape for any wires you aren’t intending to use.

- Make sure you choose the right kit for your needs. The two options are a CS bracket kit and an RX-8 kit. To find the right kit you should measure your fixture to determine which kit would work best for your needs. The main difference in kits will be that one is a flat plate design and the other allows you to break it into three sections. It will also depend on the size of your fixture and the intended purposes.

- Choose bracket kits that allow you to adjust them as you go along. This will help you with proper placement. Even after you have placed them with the tombstones, you will still be able to move them as needed.

- Select unshunted tombstones. They are ideal for converting to LED. These tombstones have four holes that will help with keeping the bracket securely placed and equally balanced.

- Divide your fixture in half in terms of wiring. Using the bulbs to measure, find the halfway point of your fixture and mark it. This will make it easier to evenly placed your brackets.

- On most fixtures, you will only have one power end. The other will be a dummy side with no actual power running to it. When working with larger fixtures, you will run your power from one end to that center bracket to give both sides power.

- It is okay to use the existing wires from the fixture to jumper power wires to the other sockets. This is a good way to recycle and the wires will get the job done without needing to purchase new wires.

- Many people screw down their brackets and then wire them. It is much easier to run your wires through and then screw them down. This also lets you make any necessary adjustments you may need to make.

These tips are the foundation of how to convert a fluorescent to an LED option.

You May Also Be Interested in These Articles...

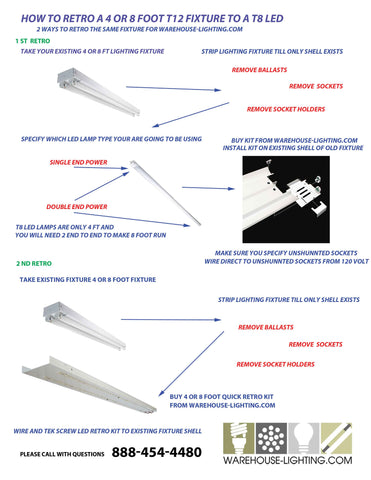

Convert t12 4 and 8 foot fixtures to LED lamps or retro kits

Info graphic showing how to convert T12 and T8 lighting fixtures to LED's. Learn How to retro fit your old lighting fixtures.

Read ArticleUpgrade Your Office Lighting with LED Magnetic Strip Retrofit Kits

A great, cost-effective option is to use LED Magnetic Strip Retrofit Kits that can be used to retrofit existing recessed troffers, vapor tight lights, industrial strip lights and wrap fixtures.

Read Article

4 Foot T8 Or T12 Retro To LED

If you are looking to switch to the impressive power and energy-saving efficiency of LED lighting solutions, you don’t need to buy all new fixtures. In fact, converting a 4 foot t8 or t12 ...

Watch Video High Bay LED Lighting

High Bay LED Lighting

Industrial Low Bay Lighting

Industrial Low Bay Lighting

Industrial Strip Lights

Industrial Strip Lights

Vapor Tight Lighting

Vapor Tight Lighting

LED Shop Lights

LED Shop Lights

Hazardous Area / Explosion Proof Lighting

Hazardous Area / Explosion Proof Lighting

Loading Dock Lights

Loading Dock Lights

Construction / Portable Lighting

Construction / Portable Lighting

High Temperature LED Lights

High Temperature LED Lights

Industrial Ceiling Fans

Industrial Ceiling Fans

LED Work Lights

LED Work Lights

Networked Controlled Lighting

Networked Controlled Lighting

NEW Warehouse Lighting Fixtures

NEW Warehouse Lighting Fixtures

American Made Industrial Lighting

American Made Industrial Lighting

Clearance

Clearance

Troffer Lights

Troffer Lights

LED Flat Panel Lights

LED Flat Panel Lights

Drop Ceiling Lights

Drop Ceiling Lights

Suspended LED Lights

Suspended LED Lights

LED Cylinder Lights

LED Cylinder Lights

Exit / Emergency

Exit / Emergency

Wrap Lighting Fixtures

Wrap Lighting Fixtures

Gooseneck and Barn Lights

Gooseneck and Barn Lights

Stairway & Corridor Lighting

Stairway & Corridor Lighting

Hospital Bed Lights

Hospital Bed Lights

Recessed Lighting

Recessed Lighting

Wafer Lighting

Wafer Lighting

RGB LED Lights

RGB LED Lights

Grow Lights

Grow Lights

Refrigeration Lighting

Refrigeration Lighting

Commercial Sign Lights

Commercial Sign Lights

LED Track Lighting Fixtures & Systems

LED Track Lighting Fixtures & Systems

UV Disinfecting Lights & Air Purifier Fixtures

UV Disinfecting Lights & Air Purifier Fixtures

American Made Commercial Lighting

American Made Commercial Lighting

LED Flood Lights

LED Flood Lights

Outdoor Wall Lights

Outdoor Wall Lights

LED Area Lights

LED Area Lights

Parking Lot Lights & Poles

Parking Lot Lights & Poles

Outdoor Post Top Lights

Outdoor Post Top Lights

LED Stadium Lighting

LED Stadium Lighting

Canopy Lights

Canopy Lights

Security & Motion Sensor Lights

Security & Motion Sensor Lights

LED Bollard Lights

LED Bollard Lights

Outdoor LED Linear Light Fixtures

Outdoor LED Linear Light Fixtures

Solar Powered LED Lighting

Solar Powered LED Lighting

Dusk to Dawn Lights

Dusk to Dawn Lights

Landscape Lighting

Landscape Lighting

Outdoor String Lights

Outdoor String Lights

Coastal Wildlife Lighting

Coastal Wildlife Lighting

Outdoor House Lights

Outdoor House Lights

American Made Outdoor Lighting

American Made Outdoor Lighting

Architectural Linear Lights

Architectural Linear Lights

Architectural Grid Mount Lights

Architectural Grid Mount Lights

Architectural Round Pendant Lights

Architectural Round Pendant Lights

Architectural Square Linear Lights

Architectural Square Linear Lights

Architectural X-Shaped Linear Lights

Architectural X-Shaped Linear Lights

Architectural LED Wall Packs

Architectural LED Wall Packs

Ceiling Fans

Ceiling Fans

Ceiling Lights

Ceiling Lights

Chandelier Lights

Chandelier Lights

Pendant Lighting

Pendant Lighting

Island Lights

Island Lights

Under Cabinet Lighting

Under Cabinet Lighting

Vanity Lights

Vanity Lights

Wall Sconces

Wall Sconces

LED Tape Lights

LED Tape Lights

LED Mirrors

LED Mirrors

LED Light Bulbs

LED Light Bulbs

LED Tube Lights

LED Tube Lights

LED Corn Lights

LED Corn Lights

Vintage LED Bulbs

Vintage LED Bulbs

Decorative LED Bulbs

Decorative LED Bulbs

Fluorescent Light Bulbs

Fluorescent Light Bulbs

Metal Halide Lamps

Metal Halide Lamps

LED Magnetic Strip Retrofit Kits

LED Magnetic Strip Retrofit Kits

LED Strip Light Retrofit Kits

LED Strip Light Retrofit Kits

High Bay LED Retrofit Kits

High Bay LED Retrofit Kits

LED Troffer Retrofit Kits

LED Troffer Retrofit Kits

LED Wall Pack Retrofit

LED Wall Pack Retrofit

LED Street Light Retrofit Kits

LED Street Light Retrofit Kits

Recessed Lighting LED Retrofit Kits

Recessed Lighting LED Retrofit Kits

Ballasts & Drivers

Ballasts & Drivers

Emergency Ballast For LED & Fluorescent Lights

Emergency Ballast For LED & Fluorescent Lights

Electrical Supplies & Mounting Kits

Electrical Supplies & Mounting Kits

Electrical Tools

Electrical Tools

Switches & Receptacles

Switches & Receptacles

Electrical Power Cords

Electrical Power Cords

Sensors and Timers

Sensors and Timers

Smart Home Automation

Smart Home Automation

High Bay Occupancy Sensors

High Bay Occupancy Sensors

Electric Vehicle Chargers

Electric Vehicle Chargers

Hand Dryers

Hand Dryers

LED Shop Lights

LED Shop Lights

Garage LED Light Fixtures

Garage LED Light Fixtures

Office Lights

Office Lights

Classroom Lights

Classroom Lights

Church Lights

Church Lights

Gym Lighting

Gym Lighting

Factory Lights

Factory Lights

Hospital Lights

Hospital Lights

Walkway Lights

Walkway Lights

Parking Lot Lights

Parking Lot Lights

Exterior Building Lights

Exterior Building Lights

Sports Lighting

Sports Lighting

Airport Lights

Airport Lights

NSF Rated Lights

NSF Rated Lights

TAA LED Lighting

TAA LED Lighting

Restaurant Lights

Restaurant Lights

Corridor Lights

Corridor Lights

Barn Lighting

Barn Lighting