Grocery Store Lighting for the Produce Section

Any type of public business needs to pay attention to their lighting to ensure a successful outcome. When it comes to grocery store lighting, there is no denying the importance of highlighting items in an appealing manner by way of proper illumination. One area in particular that is crucial in terms of installing the right lighting solutions is the produce section. When looking at lighting for the produce section, there are four main aspects you need to consider.

Color Temperature

One of the most important elements of lighting for the produce section is to choose the right color temperature. The color temperature of a light fixture can be seen in terms of whether the light output is more yellow (warm) or more on the blue-white (cool) side of the spectrum. When considering this important element, you want to stay away from warmer options because a cooler output will let the colors of the produce show through more easily instead of being washed out by a warmer color. The goal of lighting in this area is to help make the produce look appealing and of high standards so choose a color temperature ranging from 4000k to 4500k for a light that is white but not too blue to where it adds a tinged look to produce.

Color Rendering

Another important aspect regarding color in lighting for the produce section is the color rendering. While temperature is the output of the light on a spectrum, color rendering is how well a light picks up or highlights different colored objects. This is crucial to successful lighting for a produce area where the color of objects can range from greens and purples to oranges and reds. With a low color rendering index (CRI), the lighting fixture won’t be able to pick up as many colors or the difference between them which can make produce look less than appealing. Most shoppers choose their produce based on the vibrancy of color of the fruit or vegetables as an indicator of freshness and quality. Without a high enough color rendering index, you run the risk of making fruits and vegetables look less appealing to shoppers. A good rule of thumb is to opt for a CRI of at least 80+ as a low choice with a CRI of around 90+ being a higher performing solution for this area.

Low Heat Emitting

Another aspect of lighting that is unique to this type of area is the matter of heat production during operation. While most lighting solutions will naturally lose some energy to heat, there are certain lamp types where this problem is more prevalent. For example, incandescent and halogen bulbs can produce high levels of heat which can be an issue for any area storing perishable food items. A better bet is to opt for LED for a no heat option or compact fluorescent for a low heat emitting option.

Aries G3 LED UFO High Bay, 80/100/150 Wattage Selectable, 120-277V, 21,000 Lumen, CCT Selectable, Black Finish, Comparable to 320-400 Watt Fixture

Aries LED UFO High Bay, 100 Watt, 120-277V, 15000 Lumen, 4000K, White Finish, 2023 Best Seller

2 FT LED Linear Fixture G2, 2200 Lumen Max, 20W, CCT Selectable, 120-277V, Black or White Finish

At Warehouse Lighting, experts will help you shop for LED UFO high bay lights online. Round UFO LED high bay lights offer a great alternative to traditional metal halides. They are designed to last up to 100,000 hours, keeping you working and not worrying about replacing lights. UFO fixtures can have hook-type mounting for easy fixture upgrades or can be wired with energy-saving sensors with a plug and cord as an option. Order LED UFO high bay lights from Warehouse Lighting today!

View (84) Products

At Warehouse Lighting, our experts will help you shop for the best linear LED lighting online. Find the right solution with our suspended ceiling LED light fixtures for your office or architectural lighting needs for your business. Choose from a range of styles and color choices. Purchase suspended linear LED lighting fixtures today at Warehouse Lighting.

View (213) Products

Make sure your outdoor area is properly illuminated with our high-performing flood lights. These LED options can keep your home and loved ones safe at night.

View (371) Products

Convenience Store Lighting

For every business, lighting needs vary based on location. However, convenience store lighting is a pretty standard layout since most offer the same areas in need of illumination. When it comes to ...

Read Article

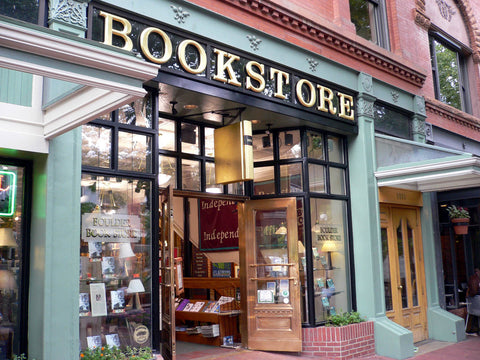

Bookstore Lighting

Make the most of this location with our tips on choosing bookstore lighting. From track to troffer, we go over all the basics for this unique retail space.

Read Article

Jewelry Lighting Suggestions

Find out the best practices for jewelry store lighting to make your accessories sparkle! Read on for more tips!

Read Article

Suspended Linear LED Lights

Watch our Suspended Linear LED Lights Product Review video. Our videos will educate you so that you can confidently purchase and install LED light fixtures, whether they are for a new installation ...

Watch Video

Center Basket Troffer

Finding the right lighting solution can be difficult. With our center basket troffer, get the performance you deserve with a fixture that looks great at the same time.

Watch Video

LCD LED Center Basket Troffer

Lighting is an important aspect of any setting. When it comes to finding an LED option perfect for your retail or office location, our LCD LED center basket troffer is a great option.

Watch Video High Bay LED Lighting

High Bay LED Lighting

Industrial Low Bay Lighting

Industrial Low Bay Lighting

Industrial Strip Lights

Industrial Strip Lights

Vapor Tight Lighting

Vapor Tight Lighting

LED Shop Lights

LED Shop Lights

Hazardous Area / Explosion Proof Lighting

Hazardous Area / Explosion Proof Lighting

Loading Dock Lights

Loading Dock Lights

Construction / Portable Lighting

Construction / Portable Lighting

Industrial Ceiling Fans

Industrial Ceiling Fans

LED Work Lights

LED Work Lights

Clearance

Clearance

Troffer Lights

Troffer Lights

LED Flat Panel Lights

LED Flat Panel Lights

Drop Ceiling Lights

Drop Ceiling Lights

Suspended LED Lights

Suspended LED Lights

Exit / Emergency

Exit / Emergency

Wrap Lighting Fixtures

Wrap Lighting Fixtures

Gooseneck and Barn Lights

Gooseneck and Barn Lights

Commercial Stairway Lighting

Commercial Stairway Lighting

Hospital Bed Lights

Hospital Bed Lights

Commercial Sign Lights

Commercial Sign Lights

UV Disinfecting Lights & Air Purifier Fixtures

UV Disinfecting Lights & Air Purifier Fixtures

Recessed Lighting

Recessed Lighting

Wafer Lighting

Wafer Lighting

RGB LED Lights

RGB LED Lights

Grow Lights

Grow Lights

Refrigeration Lighting

Refrigeration Lighting

LED Flood Lights

LED Flood Lights

Outdoor Wall Lights

Outdoor Wall Lights

LED Area Lights

LED Area Lights

Parking Lot Lights & Poles

Parking Lot Lights & Poles

Outdoor Post Top Lights

Outdoor Post Top Lights

LED Stadium Lighting

LED Stadium Lighting

Canopy Lights

Canopy Lights

Security Lights

Security Lights

LED Bollard Lights

LED Bollard Lights

Solar Powered LED Lighting

Solar Powered LED Lighting

Dusk to Dawn Lights

Dusk to Dawn Lights

Landscape Lighting

Landscape Lighting

Outdoor String Lights

Outdoor String Lights

Coastal Wildlife Lighting

Coastal Wildlife Lighting

Outdoor House Lights

Outdoor House Lights

Ceiling Fans

Ceiling Fans

Ceiling Lights

Ceiling Lights

Chandelier Lights

Chandelier Lights

Pendant Lighting

Pendant Lighting

Island Lights

Island Lights

Track Lighting

Track Lighting

Under Cabinet Lighting

Under Cabinet Lighting

Vanity Lights

Vanity Lights

Wall Sconces

Wall Sconces

LED Tape Lights

LED Tape Lights

LED Light Bulbs

LED Light Bulbs

LED Tube Lights

LED Tube Lights

LED Corn Lights

LED Corn Lights

Vintage LED Bulbs

Vintage LED Bulbs

Decorative LED Bulbs

Decorative LED Bulbs

Fluorescent Light Bulbs

Fluorescent Light Bulbs

Metal Halide Lamps

Metal Halide Lamps

Shatterproof Light Bulbs

Shatterproof Light Bulbs

LED Magnetic Strip Retrofit Kits

LED Magnetic Strip Retrofit Kits

LED Strip Light Retrofit Kits

LED Strip Light Retrofit Kits

High Bay LED Retrofit Kits

High Bay LED Retrofit Kits

LED Troffer Retrofit Kits

LED Troffer Retrofit Kits

LED Wall Pack Retrofit

LED Wall Pack Retrofit

LED Street Light Retrofit Kits

LED Street Light Retrofit Kits

Recessed Lighting LED Retrofit Kits

Recessed Lighting LED Retrofit Kits

CFL Ballasts

CFL Ballasts

Electronic Halide Ballast

Electronic Halide Ballast

Emergency Ballasts & Inverters

Emergency Ballasts & Inverters

Fluorescent Ballasts

Fluorescent Ballasts

LED Drivers

LED Drivers

High Pressure Sodium Ballasts

High Pressure Sodium Ballasts

Metal Halide (HID) Ballasts

Metal Halide (HID) Ballasts

Pulse Start Metal Halide Ballasts

Pulse Start Metal Halide Ballasts

Electric Vehicle Chargers

Electric Vehicle Chargers

Ballasts & Drivers

Ballasts & Drivers

Electrical Supplies

Electrical Supplies

Electrical Tools

Electrical Tools

Switches & Receptacles

Switches & Receptacles

Hand Dryers

Hand Dryers

Electrical Power Cords

Electrical Power Cords

Sensors and Timers

Sensors and Timers

Smart Home Automation

Smart Home Automation

High Bay Occupancy Sensors

High Bay Occupancy Sensors

Outdoor Motion Sensor Lights

Outdoor Motion Sensor Lights

Walkway Lights

Walkway Lights

Office Lights

Office Lights

Gym Lighting

Gym Lighting

Exterior Building Lights

Exterior Building Lights

Sports Lighting

Sports Lighting

Hospital Lights

Hospital Lights

Airport Lights

Airport Lights

Classroom Lights

Classroom Lights

Factory Lights

Factory Lights

Restaurant Lights

Restaurant Lights

Corridor Lights

Corridor Lights

Church Lights

Church Lights